Inside Plug Power’s Game-Changing Hydrogen Facility That’s Powering Big Names Like Amazon

Plug Power’s Louisiana Hydrogen Plant Brings Decarbonization Closer to Reality Plug Power’s 15-ton-per-day (TPD) hydrogen plant in St. Gabriel, Louisiana,…

Plug Power’s Louisiana Hydrogen Plant Brings Decarbonization Closer to Reality

Plug Power’s 15-ton-per-day (TPD) hydrogen plant in St. Gabriel, Louisiana, is nearing operational status, marking a significant step toward building a sustainable hydrogen network in North America. The facility, owned through a joint venture with Olin Corporation, demonstrates how industrial by-products can integrate seamlessly into clean energy systems. This article shines a spotlight on the plant’s technological advancements, safety milestones, and its broader impact on the transition to green hydrogen.

Cutting-Edge Technology at the Heart of Hydrogen Production

One key feature of Plug Power’s Louisiana plant is its use of Olin’s by-product hydrogen from chlorine production. By repurposing hydrogen that might otherwise go to waste, Plug Power is reducing reliance on new raw material sources while supporting a circular economy. Once operational, the plant will add 15 TPD of liquid hydrogen to the company’s supply, scaling its North American capacity to 39 TPD.

The operational plan draws from Plug Power’s success at its Woodbine, Georgia facility. Employing proven strategies from a high-performing plant ensures that the Louisiana site can operate continuously around the clock, enabling efficient production and impactful energy independence.

Central to the plant’s hydrogen output is an advanced dry-out process. This technology removes moisture and impurities from internal piping and vessels, ensuring the hydrogen produced is of high purity. Why does this matter? Impurities can lead to corrosion, freezing, and reduced fuel cell efficiency. By tackling these challenges head-on using moisture control techniques, Plug Power boosts the reliability of its fuel cells and enhances overall energy output.

Safety Standards Lead the Way

With over 412,000 safe working hours logged and zero recordable injuries, Plug Power’s Louisiana plant stands as a testament to exceptional safety practices. A disciplined approach involves rigorous adherence to process safety management protocols and job-specific safety analyses. Complex tasks like crane lifts, high-pressure testing, and vessel purging are executed with meticulous precision, setting a gold standard for safety in high-risk industrial environments.

Andy Marsh, CEO of Plug Power, emphasized, “Our team has executed hundreds of high-risk tasks without a single incident,” underscoring the importance of safety in achieving their green hydrogen goals. This effort not only safeguards the workforce but also reinforces confidence in Plug Power’s capacity to scale operations responsibly and sustainably.

Partnering for a Greener Future

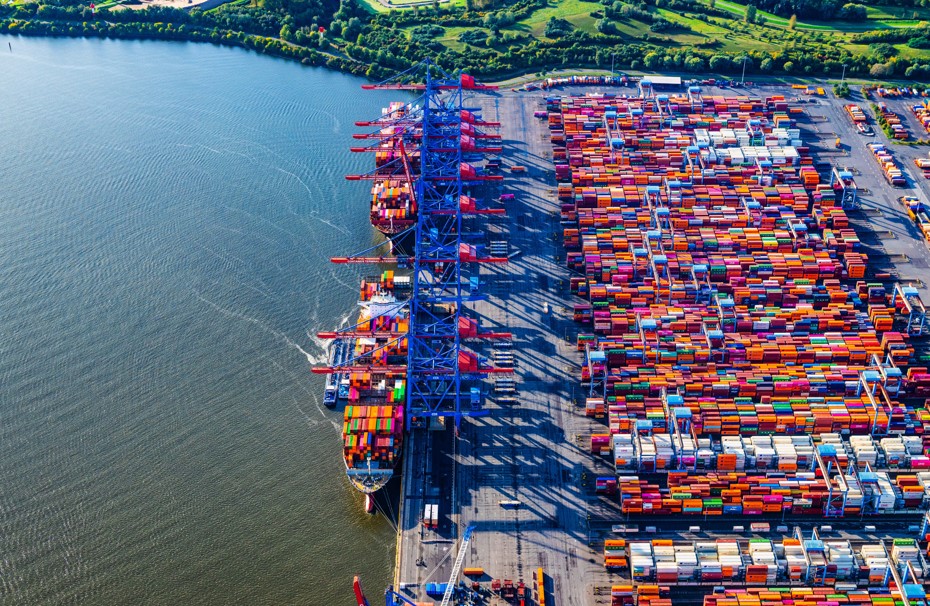

Major corporations like Amazon and Walmart are among Plug Power’s key partners, and the expanded hydrogen capacity from the Louisiana plant is expected to drive progress in their decarbonization goals. Both retailers are prioritizing sustainability in their supply chains and logistics. This facility’s green hydrogen production offers a scalable energy solution, minimizing reliance on fossil fuels and cutting carbon emissions.

With this plant contributing 15 TPD to Plug Power’s growing hydrogen network, companies that need consistent energy supply for material handling, mobility, and industrial applications can benefit from reliable hydrogen access.

Building a Comprehensive Green Hydrogen Ecosystem

Plug Power’s ambitions extend beyond individual plants. The company is working on creating a “green hydrogen highway,” a robust infrastructure that spans North America and Europe. By developing multiple hydrogen production plants, strategically sited fueling stations, and cutting-edge fuel cell technologies, Plug aims to make hydrogen a primary energy source across various industries.

The Gigafactory adds another layer of efficiency by producing electrolyzers and fuel cells at scale. This efficiency feeds into the company’s strategy to enable customers to adopt hydrogen seamlessly, whether in e-mobility or industrial power generation.

Applying Green Hydrogen Today and Tomorrow

The advancements at Plug Power’s Louisiana plant are not just engineering triumphs—they’re tools to empower industries, businesses, and communities today. Green hydrogen can be tapped into immediately to power warehouses, fuel heavy-duty vehicles, or even support localized grid power. The ability to produce hydrogen anywhere—utilizing by-products or renewable energy—makes it a versatile tool for businesses transitioning away from high-carbon fuels.

Looking ahead, this technology has the potential to rebalance how we think about and consume energy. Unlike traditional energy sources that are geographically limited, hydrogen opens doors to a decentralized energy future. For areas with abundant solar, wind, or nuclear resources, hydrogen production can scale up on-site, removing barriers of transportation and storage while reducing environmental impact.

Plug Power’s Louisiana plant is more than a milestone; it’s a blueprint for action. To capitalize on the momentum, stakeholders across sectors should accelerate the integration of hydrogen solutions into their energy strategies—whether for logistics, manufacturing, or localized energy needs.

By tackling our immediate energy challenges with sustainable solutions like green hydrogen, we can bridge the gap toward a future where clean energy is the norm, not the exception. The transition has begun, and as Plug Power’s achievements show, the tools to make it a reality are already here.

What's Your Reaction?