Scientists Developed a Process to Reclaim Composite Materials from Epoxies

A team of researchers at the University of Tokyo discovered a method to reclaim composite materials from unrecyclable epoxy resins used in applications as large as infrastructure and construction, aircraft, […] The post Scientists Developed a Process to Reclaim Composite Materials from Epoxies appeared first on American Composites Manufacturers Association.

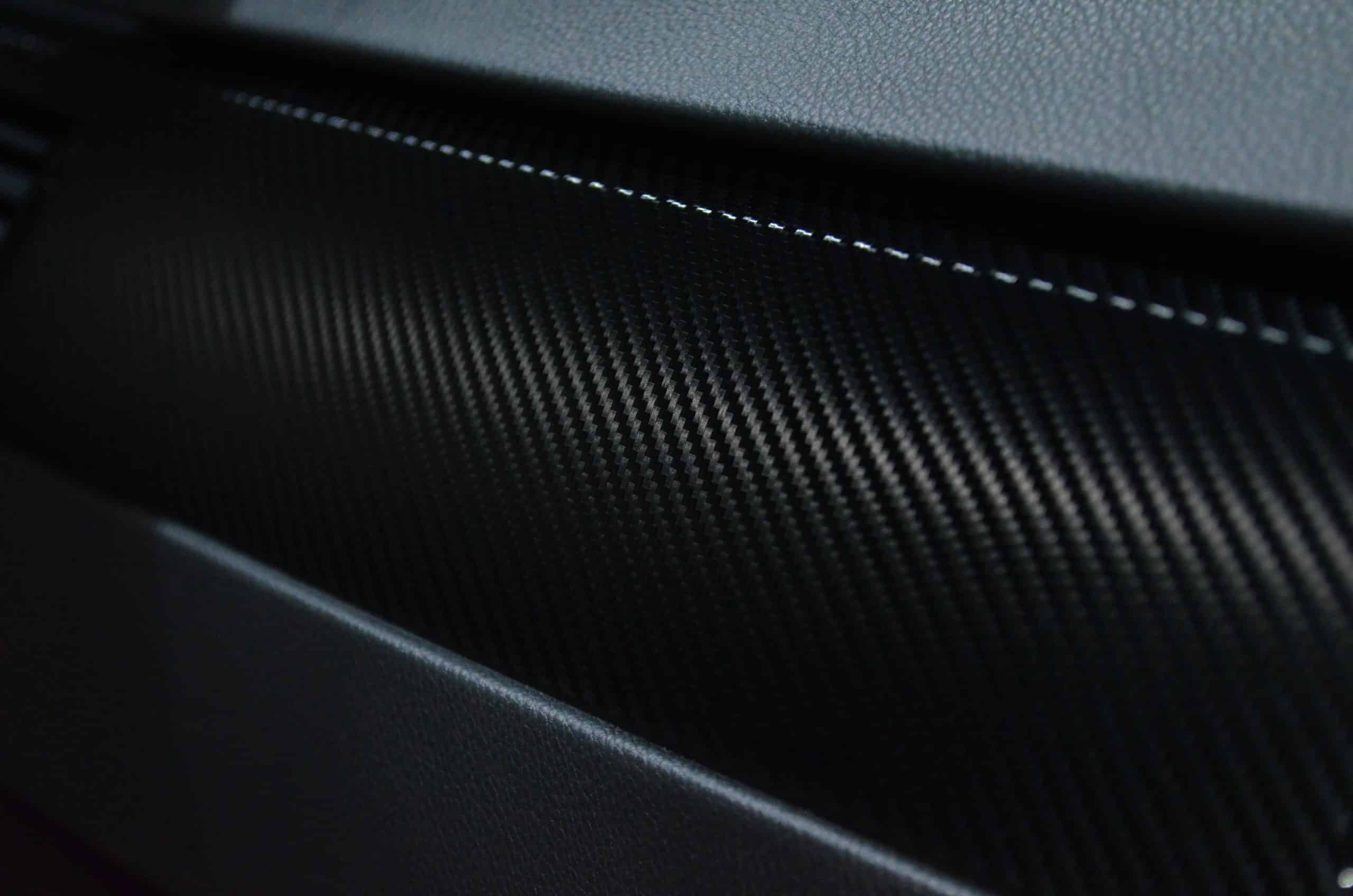

A team of researchers at the University of Tokyo discovered a method to reclaim composite materials from unrecyclable epoxy resins used in applications as large as infrastructure and construction, aircraft, and wind turbine blades to applications as small as consumer electronics and shoes. Epoxy resins pose a serious challenge to environmentally responsible disposal, and this new process allows for an efficient reclamation of the materials bonded or coated by these resins for reuse.

A bimetallic catalyst, using nickel and palladium, was developed to decompose epoxy compounds into carbon fiber, glass fiber, and phenolic compounds. The metals in the catalyst, supported by cerium oxide, work together to manage reactions between the resins and hydrogen gas at a reaction temperature of 180 degrees Celsius. The temperature allows the recovered materials to be reused.

Xiongjie Jin, associate professor at the University of Tokyo, explained, “For example, to decompose fiber-reinforced plastics, perhaps used in aircraft parts, you’d need high temperatures over 500 degrees Celsius, or strong acid or base conditions. These things have an energy cost, and the harsh conditions can damage the fibers and things you might be trying to recover. To deal with this problem, a relatively new process called catalytic hydrogenolysis shows promise, but existing catalysts for this are not reusable as they dissolve in the solvent in which the epoxy decomposition takes place. So, we created a new solid catalyst which is easily recoverable and reusable.”

“We were pleased to see experimental results that closely matched our expectations about how this process would work, but we were nicely surprised when we realized the catalyst could be reused at least five times without any reduction in its performance,” Jin continued. “As our catalyst is effective at cleaving carbon-oxygen bonds, with modification, it might even work with other plastics as well, as they contain those bonds too.”

The research team is delving into procedures and materials to make the process more commercially viable.

The post Scientists Developed a Process to Reclaim Composite Materials from Epoxies appeared first on American Composites Manufacturers Association.

What's Your Reaction?