The impact of impurity concentrations in gallium-doped p-type silicon ingots

The University of Konstanz and Chinese panel maker Longi have assessed the impact of gettering on LeTID in industrial Czochralski grown gallium-doped p-type silicon ingots and have found that defect density depends on impurity concentrations in the melt, which are observed in the case of interstitial iron concentrations.

The University of Konstanz and Chinese panel maker Longi have assessed the impact of gettering on LeTID in industrial Czochralski grown gallium-doped p-type silicon ingots and have found that defect density depends on impurity concentrations in the melt, which are observed in the case of interstitial iron concentrations.

A group of researchers from the University of Konstanz in Germany and Chinese solar module manufacturer Longi have investigated the impact of impurity concentrations caused by gettering on the long-term stability of charge carrier lifetime in recharged Czochralski-grown silicon (RCz-Si).

Gettering is widely used in the PV manufacturing industry. It involves three steps and is utilized during crystal growth to remove containments and other forms of defects in wafers. Through this process, the impurities are initially released into a solid solution and then undergo diffusion through the silicon. Finally, they are trapped in an area away from the active circuit regions of the wafer.

Gettering is already embedded in most of the current solar cells, through phosphorus diffusion in PERC or PERx devices, as well as in Al-BSF cells. It is also embedded in TOPCon solar cells, although its effectiveness varies a lot, and in silicon heterojunction cells it can be used as a pre-treatment to improve the quality of silicon substrates.

“In our research, state-of-the-art material from the industrial Czochralski melt recharging process was investigated regarding its quality,” the research's lead author, Joshua Kamphues told pv magazine. “Thereby, the long-term stability of material quality was analyzed in terms of charge carrier lifetime for wafers from subsequently pulled ingots with varying impurity concentrations. We could hereby demonstrate how the crystal growth process can actually impact the degradation extent in current industrial wafer material.”

In the paper “The impact of gettering on LeTID in industrial Czochralski-grown gallium-doped p-type silicon ingots with melt recharging,” published in Solar Energy Materials and Solar Cells, Kamphues and his team explained that they used a lifetime-equivalent defect density standard known ΔNleq to quantify the impact of observed defect kinetics during light and elevated temperature induced degradation (LeTID).

Over time, LeTID can cause significant performance losses in PV modules in the field. The problem was first recognized around 2012; the industry did not know the exact cause behind it, but it has been quick to develop mitigation strategies.

For their analysis, the scientists utilized wafers provided by Longi, which were cut from ingots obtained through two different RCz-Si growth processes, during which nine ingots were pulled with different lengths and thicknesses of 170 µm and 160 µm. The passivation layer was deposited through plasma-enhanced chemical vapor deposition (PECVD).

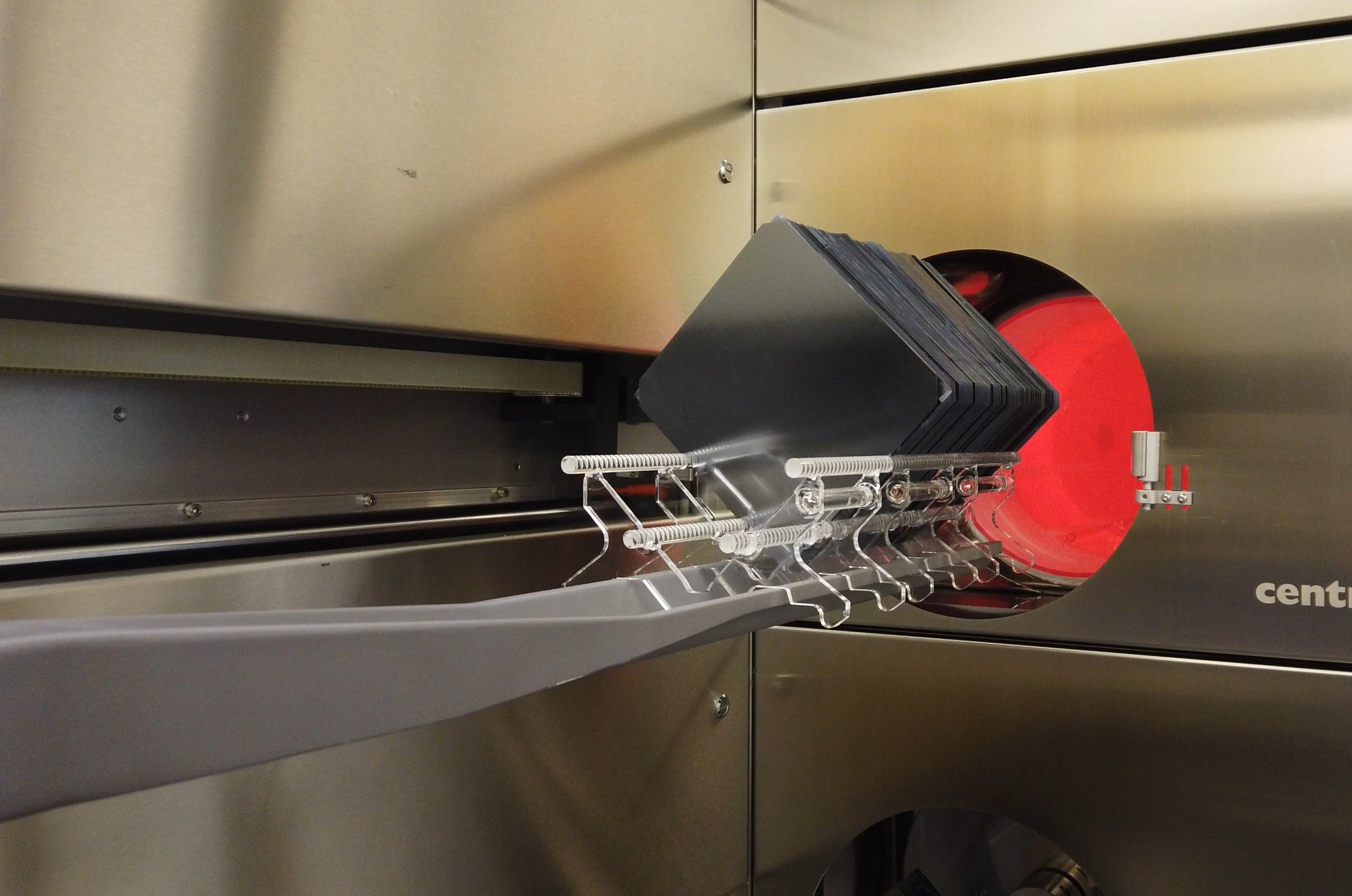

“All wafers were fired in an industrial belt furnace. Different set temperatures were used to achieve a sample peak temperature measured at 800 C, monitored using a k-type thermocouple pushed onto the center of the sample,” the research team stressed, noting that during the whole gettering process it monitored impurity concentrations during melt recharging by iron (Fe) concentration.

“A particular challenge was that we could only indirectly track elemental impurity concentrations of our material except for the iron concentration, which could be determined,” Kamphues further explained. “The higher LeTID extent for subsequently pulled ingots could therefore be correlated with higher impurity concentrations, but not to a specific impurity. The fact that a gettering step reduces the interstitial Fe content, but shows no effect on LeTID extent, leads to the conclusion that Fe itself is not directly involved in the LeTID process.”

Moreover, other experiments with iso-generative treatments showed that the LeTID kinetics were different for wafers at different ingot positions. “It was surprising to us that for iso-injective treatment the LeTID kinetics were the same for wafers from different ingots despite the significantly changed LeTID extent. Therefore, we could show that an increased impurity level in our samples only affects LeTID extent, but not LeTID kinetics,” Kamphues concluded.

He also explained that, with the current shift towards n-type Cz-Si, the industry is highly interested in the long-term stability behavior of this type of material. “We are currently investigating industrial melt-recharged n-type material with various dopant elements and will report regarding this topic in the upcoming SiliconPV conference in April,” he concluded.

What's Your Reaction?