This Hydrogen Fuel Cell Hits 393 kW Goal Fast – And It’s Built for Endless Applications

Ricardo’s Breakthrough in Hydrogen Fuel Cell Technology Marks a Leap Toward Clean Energy Ricardo, a global leader in engineering and…

Ricardo’s Breakthrough in Hydrogen Fuel Cell Technology Marks a Leap Toward Clean Energy

Ricardo, a global leader in engineering and clean energy innovation, has hit a significant milestone in green technology. The company’s multi-stack hydrogen fuel cell module achieved a remarkable 393 kW of net electrical power within only three months of development. This achievement is part of the Sustainable Hydrogen Powered Shipping (sHYpS) project, a key initiative under the European Union’s Horizon Europe program aimed at decarbonizing the maritime sector.

What separates Ricardo’s fuel cell system from others lies in its modular design. This innovative architecture integrates multiple hydrogen fuel cell stacks, resulting in high power density, scalability, and a zero-emissions energy source. The technology is scalable for various applications, including maritime, rail, stationary power, and off-highway energy needs—offering a versatile solution for industries transitioning to greener operations.

Behind the Technology: How Hydrogen Fuel Cells Work

At the core of Ricardo’s success is the hydrogen fuel cell, a system that uses electrochemical reactions to produce electricity. Hydrogen, fed into the fuel cell, reacts with oxygen from the air, generating electricity and water vapor as its only byproduct. There’s no combustion, no greenhouse gases—just clean, renewable energy.

Ricardo’s engineering team achieved this breakthrough using their virtual engineering toolchain. This advanced framework reduces the time, costs, and risks associated with physical prototyping. It also provides a detailed understanding of system performance under a variety of conditions, accelerating the development process. For example, the Ricardo team completed full transient ship operation test cycles shortly after achieving maximum power output, demonstrating the reliability and durability of their system.

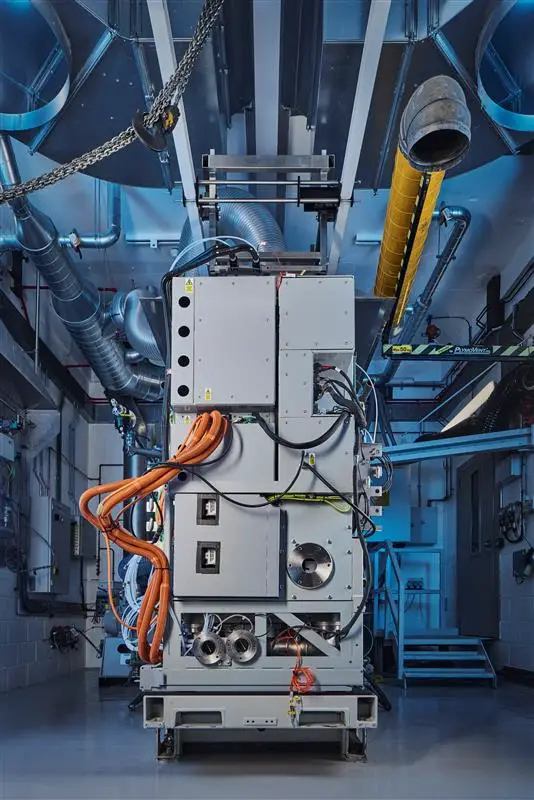

Ricardo’s hydrogen fuel cell system – Image Credit Ricardo

Further emphasizing safety and adaptability, Ricardo has secured Lloyd’s Register’s Approval in Principle, ensuring the system meets rigorous safety standards for ocean-going applications. This step not only advances maritime decarbonization but also opens the door for further adoption across industries.

Containerized Solutions for Maximum Impact

To make hydrogen fuel cells even more versatile, Ricardo has developed a containerized solution. This modular set-up allows multiple fuel cell modules to be housed in custom containers, with integrated DC-DC power conversion systems. A single container can achieve power outputs of up to 3 MW, while two containers combined can produce 6 MW. To put that into perspective, this is enough power to operate a 50,000-tonne, 1,000-passenger cruise ship during zero-emission operations.

This transportation-ready design ensures that industries can scale up operations without compromising efficiency or durability. It’s an exciting development, particularly for maritime shipping, where clean energy solutions have long been limited by technological and logistical constraints.

The Role of the sHYpS Project in Accelerating Hydrogen Adoption

The sHYpS project, co-funded by the European Union and Innovate UK, plays a central role in advancing hydrogen technologies. Aiming to decarbonize the shipping industry and meet the International Maritime Organization’s (IMO) 2030 and 2050 targets, the project combines multi-disciplinary expertise from partners across Europe.

One of its key innovations is a novel swappable liquid hydrogen storage solution that integrates seamlessly into vessels. This allows easy refueling and ensures compatibility with different ship designs. By concentrating on scalable logistics, the sHYpS initiative is also establishing a supply chain for liquid hydrogen in key ports, like the Port of Bergen, to ease the transition for the shipping industry.

Projections for this system show wide adoption potential, with one Viking Ocean Cruise vessel already slated to test the hydrogen storage system during its shakedown voyage by 2026. And this isn’t a one-off—it’s estimated that hundreds of commercial vessels, from river ships to deep-sea cruisers, could adopt similar systems within the next decade.

Ricardo’s hydrogen fuel cell system introduces several notable features and advancements that set it apart:

-

Modular Multi-Stack Design: Unlike many traditional systems, Ricardo’s fuel cell module integrates multiple stacks into a single system. This modular architecture allows for high power density and scalability, making it adaptable for various applications, from maritime to stationary power generation.

-

Rapid Development Timeline: Achieving 393 kW of net electrical power in just three months from initial start-up is a testament to Ricardo’s advanced engineering processes. Their virtual engineering toolchain played a crucial role in accelerating development while reducing costs and risks.

-

Containerized Solutions: Ricardo has developed a containerized system that combines multiple fuel cell modules, enabling power outputs of up to 6 MW when scaled. This design is particularly suited for large-scale applications like powering cruise ships, offering a practical and portable zero-emission energy solution.

-

Safety and Certification: The system has received Lloyd’s Register’s Approval in Principle, ensuring it meets stringent safety standards for ocean-going applications. This certification is critical for adoption in the maritime sector, where safety is paramount.

-

Swappable Hydrogen Storage: As part of the sHYpS project, Ricardo is working on a swappable liquid hydrogen storage solution. This innovation simplifies refueling and enhances compatibility with various vessel designs, addressing logistical challenges in hydrogen adoption.

-

Versatility Across Industries: While initially developed for maritime use, the system’s design is versatile enough to be applied in rail, off-highway vehicles, and stationary power generation. This broad applicability makes it a game-changer for industries seeking to decarbonize.

-

Focus on Efficiency and Durability: Ricardo’s system is engineered to maintain high efficiency and durability, even under demanding conditions. This ensures long-term reliability, which is crucial for industries transitioning to hydrogen-based energy.

-

Integrated DC-DC Power Conversion: The inclusion of onboard DC-DC power conversion in their containerized solutions enhances efficiency and simplifies integration into existing systems

Today, other sectors can start leveraging containerized hydrogen fuel cell systems for stationary emergency backup power or operations where diesel generators dominate. Urban environments with high air quality concerns could benefit from hydrogen-powered public transport systems. Over time, as infrastructure for hydrogen production and storage expands, the technology may also become a key driver for decarbonizing aviation and heavy industry.

The timeline for widespread adoption depends on the collective effort of innovators, policymakers, and industries to continue supporting projects like sHYpS and scaling green hydrogen production. Ricardo’s groundbreaking engineering demonstrates that clean, high-powered solutions are possible, and with projects like these, the future of zero-emissions energy is closer than we might think.

What's Your Reaction?