Green Hydrogen Takes Center Stage in Schweinfurt – Here’s What It Means for Mobility

Tyczka Hydrogen’s New Project and Key Investment Tyczka Hydrogen is making headlines with its announcement to build a state-of-the-art 5…

Tyczka Hydrogen’s New Project and Key Investment

Tyczka Hydrogen is making headlines with its announcement to build a state-of-the-art 5 MW electrolysis plant and hydrogen refueling station in the Port of Schweinfurt, Germany. This ambitious project received a €5 million grant from the Bavarian Ministry of Economic Affairs, signaling strong governmental support aimed at advancing Germany’s green energy infrastructure.

The new facility is designed to provide up to 2.2 tons of green hydrogen daily. Hydrogen from the plant will serve critical markets, including mobility, industry, and research, showcasing a versatile application for this renewable energy source. Positioned close to the SuedLink high-voltage direct current grid connection, the plant will leverage renewable wind power from northern Germany and offshore installations as a primary energy source.

Construction is expected to kick off later this year, with operations projected to begin by the end of 2026. Once functional, this facility will be integral to decarbonizing heavy-duty transport fleets and industrial solutions in the region—goals that align with Germany’s broader renewable energy strategies.

A Strategic Location for a Green Energy Hub

One notable highlight is the facility’s position within the industrial hub of Schweinfurt. The site’s location wasn’t chosen by coincidence; Schweinfurt lies at a crossroads of major highways, ensuring the efficient distribution of hydrogen for industrial users and hydrogen-powered vehicles.

The Schweinfurt hub is envisioned as a centralized node that combines hydrogen production and refueling capabilities. This setup enhances accessibility and contributes to creating an ideal environment for emissions-free transit, from public buses to heavy-duty trucks. Its proximity to the SuedLink grid also allows Tyczka Hydrogen to tap into Germany’s sprawling network of renewable energy facilities, turning wind power into a key input for hydrogen generation.

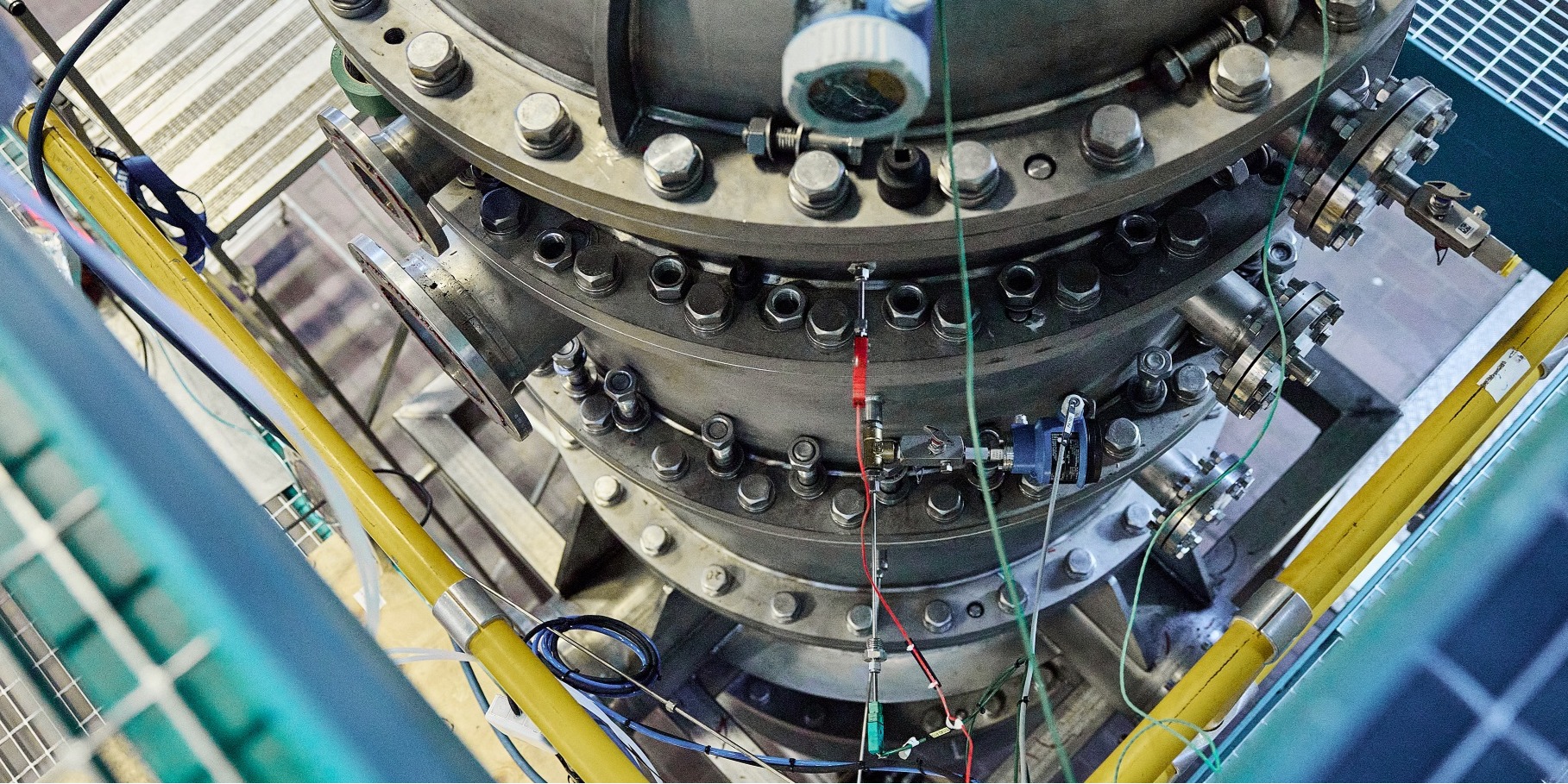

The Technology Behind Green Hydrogen Production

At the heart of Tyczka Hydrogen’s project is the electrolysis process. Electrolysis involves splitting water into hydrogen and oxygen using electricity. When powered by renewable energy, like wind or solar, this method generates “green hydrogen”—a sustainable and carbon-neutral fuel. The production at Schweinfurt will primarily rely on photovoltaic and wind energy sources, underscoring the company’s emphasis on clean energy adoption.

The company’s ability to produce 2.2 tons of hydrogen daily underscores the growing efficiency of electrolysis technology. Hydrogen will then be distributed for use in applications where electrification is less practical, such as long-haul transport and certain heavy industrial processes.

Why This Project Matters

This Schweinfurt initiative reflects the strategic importance of green hydrogen in global decarbonization efforts. As sectors like heavy industry and long-distance transport wrestle with reducing their carbon footprints, hydrogen provides one of the most viable alternatives to fossil fuels.

Mobility and logistics will greatly benefit from this project. Hydrogen-powered vehicles, particularly those used in public transport and freight industries, offer advantages like fast refueling times and high energy density, making them ideal for continuous and demanding operations. The ability to serve these sectors locally with green hydrogen could significantly accelerate Germany’s transition toward zero-emissions transport networks.

Furthermore, industrial processes that currently rely on natural gas or coal combustion—such as steelmaking—can integrate hydrogen to curtail their emissions. This versatility makes hydrogen one of the most valuable tools for meeting Europe’s ambitious carbon neutrality targets by 2050.

Timelines and the Road Ahead

Tyczka Hydrogen plans to begin construction in 2025, with the facility set to become operational by the end of 2026. While this may seem far off, the timeline aligns with the broader push in Germany to scale up hydrogen infrastructure over the next decade. By the time the facility is commissioned, Germany is expected to have advanced its hydrogen distribution networks, making Schweinfurt’s green hydrogen production even more impactful regionally and nationally.

Bringing Hydrogen to Use in Everyday Life

This technology isn’t just about the future—it’s applicable today. Green hydrogen already powers hydrogen fuel cell vehicles, from passenger cars like the Toyota Mirai to buses and even forklifts in industrial settings. It’s also paving the way for cleaner shore power at ports and sustainable heating solutions in residential and commercial buildings.

Efforts like Tyczka’s are part of a much larger puzzle, building the foundation for more affordable, accessible hydrogen solutions worldwide. By creating hubs where production, distribution, and consumption meet, companies can gradually normalize hydrogen use, making it a relatable and functional part of everyday life.

Looking forward, projects like this could also address some of hydrogen’s initial hurdles, such as transportation and storage challenges. Improvements in fuel cell efficiency and the growing network of filling stations will eventually help hydrogen compete on a level playing field with traditional fuels.

What's Your Reaction?