The impact of wind load effects on offshore floating photovoltaics

Researchers have investigated the aerodynamic performance of a single floating PV setup of 16 panels, as well as an array that combined 15 such setups. They found that drag coefficient distributions and wind pressure effects on PV systems vary by inlet angle. They have also identified cost-saving opportunities through material optimization.

Researchers have investigated the aerodynamic performance of a single floating PV setup of 16 panels, as well as an array that combined 15 such setups. They found that drag coefficient distributions and wind pressure effects on PV systems vary by inlet angle. They have also identified cost-saving opportunities through material optimization.

A research group led by National Taiwan University of Science and Technology scientists has investigated the aerodynamic performance of floating photovoltaic (FPV) systems under different wind speeds and turbulence intensities and has identified cost-saving opportunities through material optimization.

“This study provides a detailed wind tunnel investigation of a scaled offshore FPV system, offering critical insights into its aerodynamic behavior in both single island and arrayed configurations under diverse wind conditions and turbulence intensities,” the group said. “It emphasizes the significant impact of wind-induced drag and lift forces on the structural integrity of FPV systems, especially in extreme offshore scenarios such as hurricanes.”

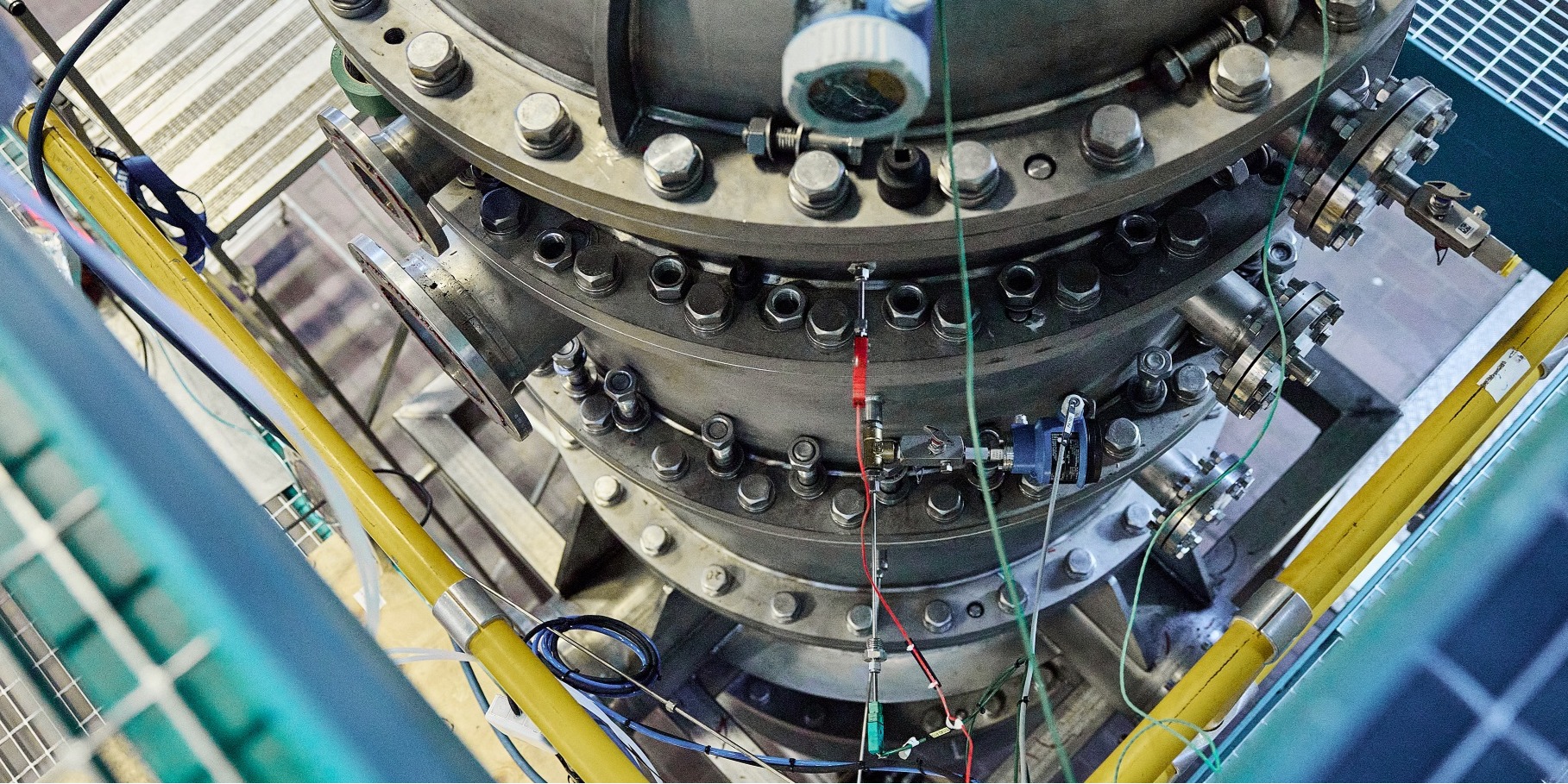

Both the single-island and arrayed configurations were manufactured as 1/50 scale models. The island was signed as a floating unit with 16 PV panels. It had dimensions of 19.5 cm in length, 9.5 cm in width, and 3.8 cm in height.

While the single island served as the baseline for understanding the different forces, the island array was designed to study the interaction effects between multiple PV units. More specifically, it included 15 single island models in a 3 X 5 configuration, covering a horizontal area of 60 cm x 60 cm.

Experimental results

“The FPV system models were tested in a controlled wind tunnel environment. The testing section of the wind tunnel measures 2.2 m in width, 1.8 m in height, and 12.0 m in length, along with the PV panel’s array model placed at the center of the test section turntable with 3 m in diameter and 4.5 m away from the inlet,” the academics explained. “To simulate realistic offshore wind conditions, two turbulence intensities were generated using grids placed at 1.8 m and 2.0 m upstream from the leading edge of the end plate.”

Data acquisition utilized the 56 pressure taps every single model had. Those holes were strategically placed, and the pressure they experienced was transferred to an acrylic disk through the steel pipe and then transmitted to the pressure-scanning raft through the plastic hose. The sampling time of wind pressure measurement was set to 5 minutes, and the sampling frequency was set to 300 times per second.

The experimental tests showed that drag coefficient distributions and wind pressure effects on PV systems vary by inlet angle. “Positive and negative pressures create force couples, influencing panel rotation,” the team stressed. “Lower wind angles experience stronger disturbances due to turbulence, especially on windward surfaces, while higher angles reduce disturbances and suction effects. Overall, wind pressure changes significantly at smaller angles, decreasing as the angle increases.”

More specifically, at 0◦ and 30◦ inlet angles, negative pressure on the top and positive on the bottom surface increases drag, further amplified by turbulence. At 60◦, drag slightly rises due to pressure redistribution, while 90◦ the pressure balance reduces drag. “Similarly, lift forces are low at 0◦, increase with turbulence at 30◦, peak at 60◦, and decrease again at 90◦, even under turbulent conditions,” they added.

Economic evaluation

The group also found that turbulence significantly reduces the average wind coefficient, a measurement that describes how much wind force acts on the panels. The results showed that higher upstream turbulence lowered the coefficient by 70–80% compared to lower turbulence. “Smaller angles experience stronger wind disturbances, which turbulence amplifies. Turbulence increases overall wind loads and variability across wind angles, impacting aerodynamic forces,” the researchers highlighted.

As for the financial aspect, the team has compared two types of polyethylene commonly used in PV systems to support solar panel arrays – high-density polyethylene (HDPE) and medium-density polyethylene (MDPE). While the first is more widely used due to its strength, the latter offers a more cost-effective alternative.

“Replacing HDPE with MDPE in central areas, where drag and lift forces are lower, can reduce system costs by 10.2%,” the group said. “This substitution balances strength and cost, making larger floating PV systems more economical and efficient.”

The results were presented in “Experimental investigation and economic evaluation of wind impacts on the solar panel array of a floating photovoltaic (FPV) system across different turbulence intensities,” published in Energy Nexus. Aside from the National Taiwan University of Science, researchers from Taiwan’s Industrial Technology Research Institute have conducted the study.

What's Your Reaction?