Chinese scientists build copper indium sulfide solar cell with 10.44% efficiency

Copper indium sulfide (CuInS2) are still far from reaching commercial maturity but new titanium dioxide nanorod arrays can reportedly improve their light trapping, charge separation, and carrier collection.

Copper indium sulfide (CuInS2) are still far from reaching commercial maturity but new titanium dioxide nanorod arrays can reportedly improve their light trapping, charge separation, and carrier collection.

A group of scientists from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences (CAS) has fabricated a solar cell based on an absorber made of copper indium sulfide (CuInS2), a material that shows great potential for PV applications applications due to its tunable optical and electronic properties, low toxicity, and relatively low costs.

This compound can be easily tuned from n-type to p-type simply by modifying its chalcogenide content and is commonly considered a possible, non-toxic alternative to cadmium-based semiconductors. Furthermore, its energy bandgap is perfectly suitable for the visible portion of the solar irradiance spectrum.

Several strategies have been developed by the scientific community to improve its stability and properties, including morphological engineering and the formation of heterojunctions to improve charge separation, however CuInS2 solar cell technologies have so far been unable to reach commercial maturity.

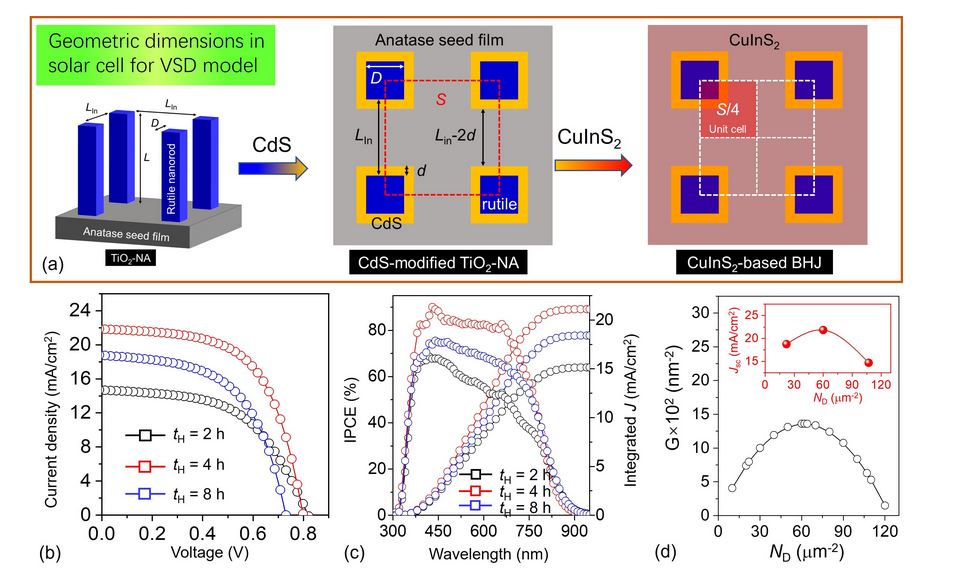

With this in mind, the CAS researchers have developed titanium dioxide nanorod arrays (TiO₂-NA) with controllable spacing that reportedly improve the cell's light trapping, charge separation, and carrier collection.

The researchers said they have been able to calibrate the number density (ND) of the nanorods without altering their dimensional features.

“Traditional fabrication methods link rod density, diameter, and length—if one parameter is adjusted, the others shift accordingly, often affecting device efficiency,” they further explained. “By carefully extending the hydrolysis stage of a precursor film, we showed that longer ‘gel chains' assemble into smaller anatase nanoparticles. When the anatase film is subjected to hydrothermal treatment, those anatase nanoparticles convert in situ into rutile ones, serving as seeds for nanorod growth. The hydrolysis stage provides an effective way to control the rod density without altering the nanorod dimensions.”

The TiO₂-NA films were fabricated with constant rod diameter and height and were incorporated into low-temperature-processed CuInS₂ solar cells that achieved a power conversion efficiency of 10.44% when tested under standard illumination conditions.

Through a Volume-Surface-Density (VSD) model, the research team observed how rod density and spacing influence light harvesting, charge separation, and carrier collection.

“This research overcomes the limitations of traditional methods for regulating nanostructures by establishing a complete system linking macro-process regulation-microstructure evolution-device performance optimization,” the scientists said.

The PV device was described in the study “Unveiling Growth and Photovoltaic Principles in Density-Controllable TiO2 Nanorod Arrays for Efficient Solar Cells,” published in small methods.

What's Your Reaction?