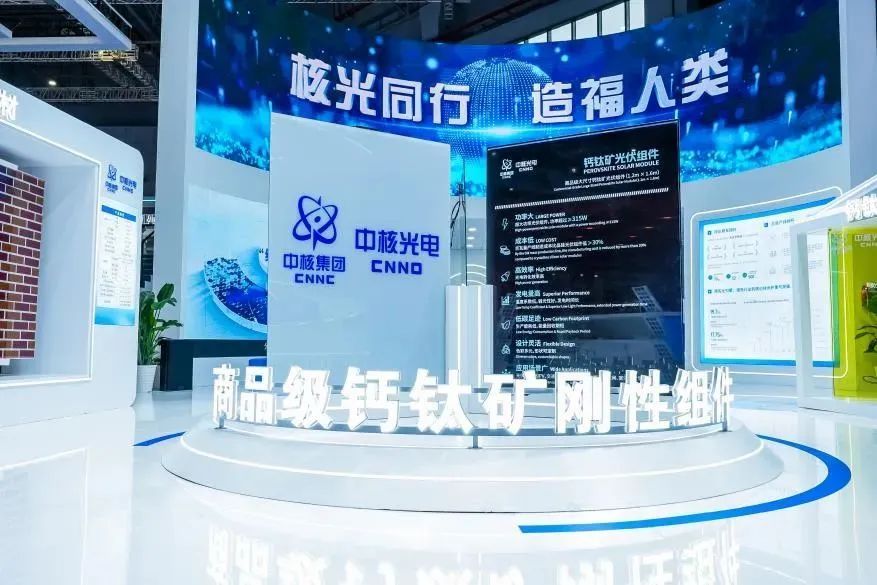

CNNP Optoelectronics unveils 16.5%-efficient perovskite solar module

CNNP Optoelectronics has started producing a 1,200 mm × 1,600 mm perovskite solar module on a 200 MW pilot line, marking a step toward scaling commercial manufacturing of next-generation PV technologies.

CNNP Optoelectronics has started producing a 1,200 mm × 1,600 mm perovskite solar module on a 200 MW pilot line, marking a step toward scaling commercial manufacturing of next-generation PV technologies.

CNNP Optoelectronics, a solar subsidiary of China National Nuclear Corp. (CNNC), presented a new perovskite solar module at the recent 2025 SNEC International Photovoltaic Power Generation and Smart Energy Conference in Shanghai.

The product measures 1,200 mm × 1,600 mm and has a power conversion efficiency of 16.5%, as certified by TÜV SÜD.

The module features a dual-glass structure and anti-PID materials, enabling operation at 1,500 V and withstanding wind speeds up to 275 km/h. The manufacturer said it is designed for use in harsh environments such as high altitudes and coastal areas.

Technical highlights include the use of a Poly-4PACz polymer self-assembled monolayer that forms a nanometer-scale passivation interface. This reportedly allows the module to retain more than 95% of its initial efficiency after prolonged exposure to temperatures of 85 C.

Structural stability improvements include a 30 nm water–oxygen barrier layer applied via atomic layer deposition, a sealed mechanical interlock enclosure, and an adjustable wiring interface that protects against salt and dust corrosion.

The module is currently produced at a 200 MW pilot line built to “dark factory” standards, meaning it operates without human labor. The line uses domestically developed equipment, from deposition tools to encapsulation systems.

One key innovation is the module’s stable production in environments without temperature or humidity control, reducing both capital and operating expenses, the company said.

CNNP Optoelectronics said the process is also cost- and resource-efficient. Compared to crystalline silicon cells, production time is reduced by 40%, materials use by 60%, and energy consumption by 80%.

The module’s life-cycle carbon footprint is reportedly 70% lower. The design also minimizes the use of toxic materials such as lead. The company expects large-scale production will lower costs to under CNY 0.5 ($0.07)/W, about 30% less than traditional silicon modules.

CNNP Optoelectronics said it plans to start building a gigawatt-scale production facility in 2026, with commercial operations expected in 2028.

What's Your Reaction?