Green hydrogen economy: Evonik is building a plant for anion exchange membranes

Green hydrogen economy: Evonik is building a plant for anion exchange membranes Essen. Evonik is building a pilot plant in Marl, Germany, for the production of its innovative and high-performance anion […] The post Green hydrogen economy: Evonik is building a plant for anion exchange membranes appeared first on Hydrogen Central.

Green hydrogen economy: Evonik is building a plant for anion exchange membranes

- Membrane makes water electrolysis more cost-effective

- Pilot plant for production of anion exchange membranes in Marl to start operation at the end of 2025

- Plant will also produce reinforced membranes to meet growing customer demand

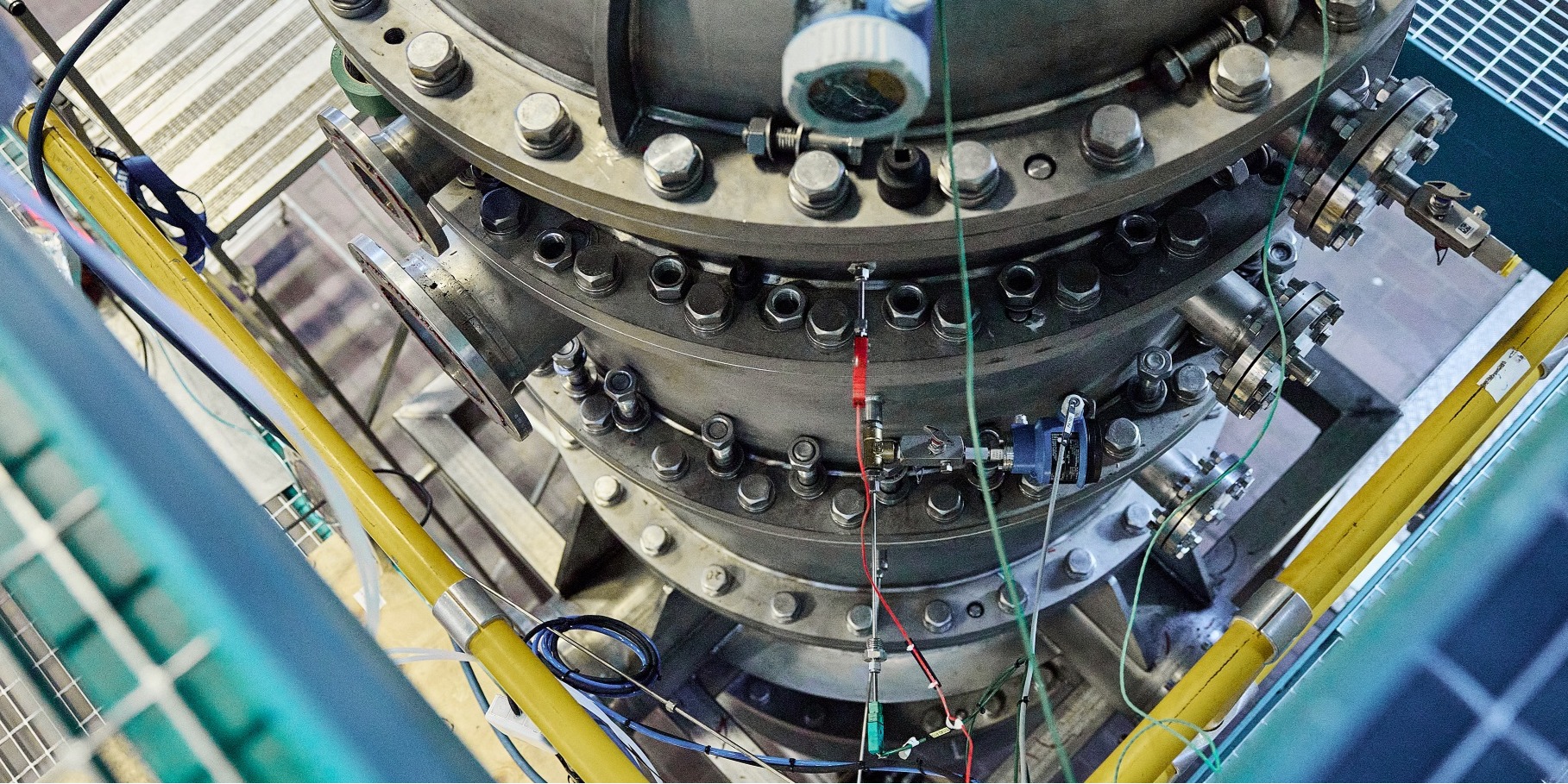

Essen. Evonik is building a pilot plant in Marl, Germany, for the production of its innovative and high-performance anion exchange membrane (AEM). Developed by Evonik the membrane is marketed under the name DURAION®.

A central element in AEM water electrolysis, DURAION® membranes enable the cost competitive production of green hydrogen. Evonik is investing a low double-digit million euro amount in the AEM plant, which is scheduled to go online at the end of 2025.

Goetz Baumgarten, head of the Membranes & Fibres product line at Evonik’s High Performance Polymers business line, says :

This strategic investment ties in with our business goals of further growing our pioneering membranes into a true enabler of the burgeoning green hydrogen economy,

The DURAION® membranes produced at the AEM plant in Marl will be at a quality suitable for use in commercial electrolyzer systems. Once fully online, the plant will be able to produce enough membranes each year to provide 2.5 GW of electrolysis capacity for hydrogen production. In addition, the plant will be able to produce reinforced membranes, directly addressing growing customer interest in this new technology.

Compared to conventional electrolysis processes, AEM technology promises lower investment costs due to the use of less expensive materials for the cells. In addition, the technology enables high current densities and very good efficiency.

Christian Däschlein, head of the New Growth Area Hydrogen Economy at Creavis, Evonik’s strategic innovation unit and business incubator, says :

The successful development of our DURAION® membrane was possible thanks to the joint efforts of Evonik’s wide-ranging expertise and technology,

The membrane is a polymer and a high-tech product: on the one hand, it has to allow anions to pass through, but on the other hand, it has to be impermeable to the gases produced in the electrolysis, such as hydrogen. It also has to be able to withstand high pressure and high temperatures.

Christian Däschlein, says :

Across our many disciplines, we were able to combine polymer design and synthesis, engineering, membrane manufacturing as well as customer and market feedback,

In the last twelve months, Evonik has steadily increased the production capacity of the intermediate products used in DURAION® membranes. The construction of the plant in Marl capitalizes on this higher capacity, and is the next step for the company in the planned expansion of its membrane business.

READ the latest news shaping the hydrogen market at Hydrogen Central

Green hydrogen economy: Evonik is building a plant for anion exchange membranes, source

The post Green hydrogen economy: Evonik is building a plant for anion exchange membranes appeared first on Hydrogen Central.

What's Your Reaction?