The Hydrogen Stream: OMV starts 10 MW H2 production plant near Vienna

OMV says it has successfully started its 10 MW green hydrogen plant at the Schwechat refinery near Vienna, while Austrian university TU Graz says it has inaugurated a hydrogen electrolysis test center at its Inffeldgasse Campus to develop and test hydrogen technologies.

OMV says it has successfully started its 10 MW green hydrogen plant at the Schwechat refinery near Vienna, while Austrian university TU Graz says it has inaugurated a hydrogen electrolysis test center at its Inffeldgasse Campus to develop and test hydrogen technologies.

OMV has announced the successful start-up of its 10 MW green hydrogen plant at the Schwechat refinery near Vienna, calling it the largest installation of its kind in Austria. The Austrian oil and gas company said it invested €25 million ($28.41 million) in the facility, which can produce up to 1,500 metric tons of green hydrogen per year. The green hydrogen will be used to produce fuels and chemicals, including sustainable aviation fuel (SAF) and renewable diesel (HVO). The installation, which uses a polymer electrolyte membrane (PEM) electrolyzer, runs entirely on renewable electricity from wind, hydro, and solar sources.

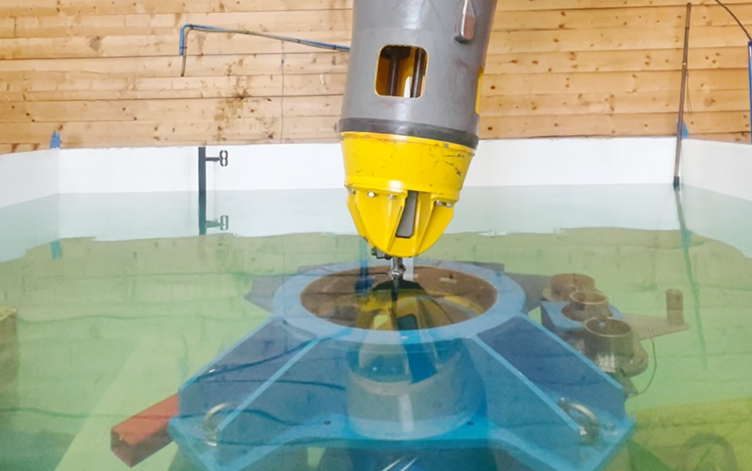

TU Graz has inaugurated a hydrogen electrolysis test center at its Inffeldgasse Campus to develop and test hydrogen technologies. The university said the 250-square-meter facility houses electrolyzers with a total capacity of 1.6 MW to 2.5 MW and includes a dedicated transformer station to ensure stable power supply, allowing researchers to simulate various electricity scenarios. At 80 bar of pressure, hydrogen flows through a pipeline to an 18-meter-high storage tank with a 190 kg (48m³) capacity. From there, it travels via a 315-meter underground pipeline to several institutes at Campus Inffeldgasse, where it is available around the clock for research. TU Graz said researchers will use the hydrogen on new and upgraded test rigs for next-generation large engines, turbines, hydrogen burners, and fuel cell stacks.

Wärtsilä said it has completed the development of the world’s first floating ammonia-to-hydrogen cracker in partnership with Höegh Evi. “This breakthrough technology enables floating import terminals to produce hydrogen at industrial-scale volumes from transported ammonia, marking a major step in the energy transition,” said the Finnish technology group. The industrial-scale ammonia cracker has a modular design that makes it compatible with hybrid floating storage and regasification units (FSRUs) and dedicated floating hydrogen terminals. It said the technology is highly scalable, with a send-out capacity of up to 210,000 tonnes of hydrogen annually. Ammonia storage can range from 10,000m³ to 120,000m³.

BMW has launched pilot operations of its first hydrogen trucks at Plant Leipzig under the European H2Haul project, working with Iveco, DHL, and TEAL mobility. The German automaker said the trucks will operate in Germany between Leipzig, Landsberg, and Nuremberg to assess drive performance in daily use, while new hydrogen refueling stations are being built in Leipzig and Hormersdorf.

What's Your Reaction?

![[Upcoming Webinar] Addressing the Wind Industry's €25 Billion Annual Wake Loss Problem](https://www.windesco.com/hubfs/Swarm%20webinar%20cover%20image.png)