Bottom-up cost model for perovskite solar module manufacturing

Scientists in Switzerland have conducted techno-economic analysis of perovskite solar module manufacturing costs in terms of levelized cost of energy and have found that these products could be competitive in the Alpine country provided that they achieve an efficiency of over 24% with a lifespan of 20 years and over 20% with a lifecycle of 30 years.

Scientists in Switzerland have conducted techno-economic analysis of perovskite solar module manufacturing costs in terms of levelized cost of energy and have found that these products could be competitive in the Alpine country provided that they achieve an efficiency of over 24% with a lifespan of 20 years and over 20% with a lifecycle of 30 years.

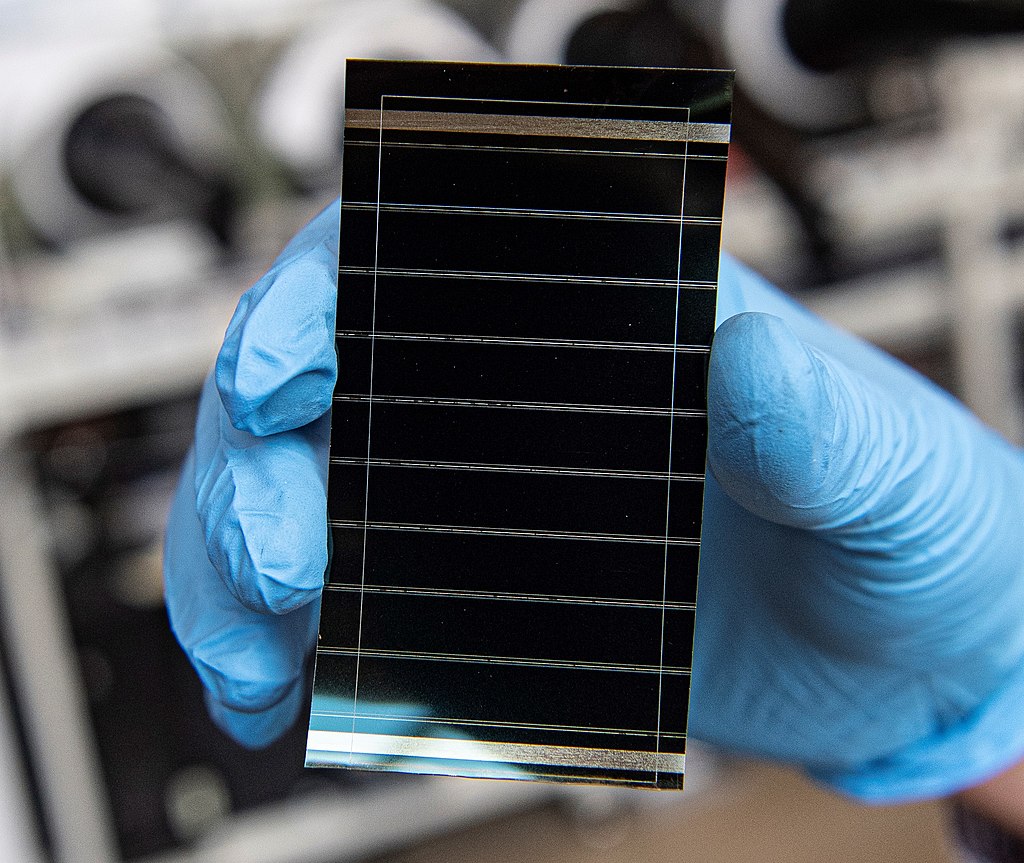

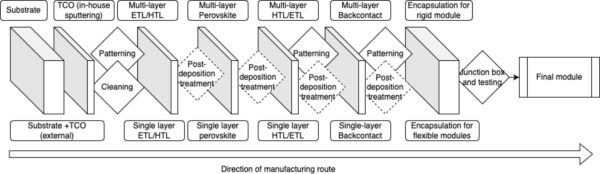

A group of scientists from the Ecole Polytechnique Fédérale de Lausanne (EPFL) has developed a bottom-up techno-economic model to assess perovskite solar module manufacturing costs and feasibility.

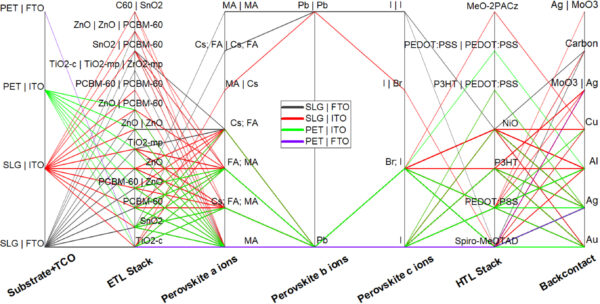

The modeling is based on existing models for PV manufacturing and principles from the chemical manufacturing industry. It considers the impact of labor scaling, waste treatment, automation, and production capacity. It also includes a database of materials for perovskite absorbers, transparent conducting oxide (TCO) substrates, electron transport layers (ETLs), hole transport layers (HTLs), and electrodes.

The scientists acknowledged that the model, however, still doesn't include manufacturing complexities such as surface passivation or other surface treatments. “The model assumes a particular module architecture including the material components and selects techniques for deposition and other required processes such as scribing and solution preparation,” they explained, noting that materials cost and equipment cost depend on the production capacity of a given manufacturing plant.

Image: EPFL; Renewable Energy, CC BY-SA 4.0

The research team specified that the module manufacturing cost included the costs for equipment, materials, factory building, automation, operations and maintenance, labor, and utilities.

The depreciation periods for the equipment and building were assumed as 7 years for the modified accelerated cost recovery system (MACRS) and 25 years for linear depreciation. The weighted average cost of capital (WACC) was assumed to be 14%, while general and administrative (SG&A) and research and development (R&D) expenses were expected to vary with production size.

The cost of energy from PV modules was evaluated in terms of levelized cost of energy (LCOE) based on the solar irradiation data in Valais, Switzerland.

Image: EPFL; Renewable Energy, CC BY-SA 4.0

The scientists also used the so-called Morris sensitivity analysis to identify the crucial parameters defining the LCOE. This methodology is commonly used to explore which parameters have the biggest influence on the model fit. This assessment showed that solar radiation, module capex, balance of system (BOS) capex area dependent, and module efficiency with relatively high non-linear effects are the most important parameters.

“LCOE can reduce by 15.7% or increase by 25.5% for a 20% change in the irradiance value, whereas for a 20% change in WACC, it can increase or decrease by roughly 7%–8%,” they emphasized. “The module capex can be considered as $50/m2, $85/m2, and $335/m2 based on the statistical data generated from the first screening as low-cost, medium-cost, and high-cost scenarios at 1000 MW production capacity.”

The overall analysis showed that the lowest possible LCOE achievable by perovskite solar modules produced in Switzerland is $0.051/kWh with low-cost materials and fabrication equipment. This LCOE level could be competitive in Switzerland, where conventional utility-scale PV project cost is estimated at $0.057/kWh, provided that perovskite PV modules have an efficiency of over 24% with a lifespan of 20 years and over 20% with a lifecycle of 30 years.

“Further, with the high-cost module, even with the highest possible efficiencies and minimum degradation rates, perovskite solar modules would not be competent in the market given the plethora of options in this highly competitive space of PV technologies and energy technologies in general,” the academics concluded.

The manufacturing cost analysis was presented in the study “Techno-economic analysis framework for perovskite solar module production at various manufacturing capacities,” published in Renewable Energy.

What's Your Reaction?