Integrated risk-cost framework for DC-coupled PV-electrolyzers

Scientists in Austria have conducted a risk analysis for four setups for coupled PV-electrolyser systems, and tested them under three use cases. They calculated failure probability as well as the levelized cost of hydrogen and its risk-weighted variant.

Scientists in Austria have conducted a risk analysis for four setups for coupled PV-electrolyser systems, and tested them under three use cases. They calculated failure probability as well as the levelized cost of hydrogen and its risk-weighted variant.

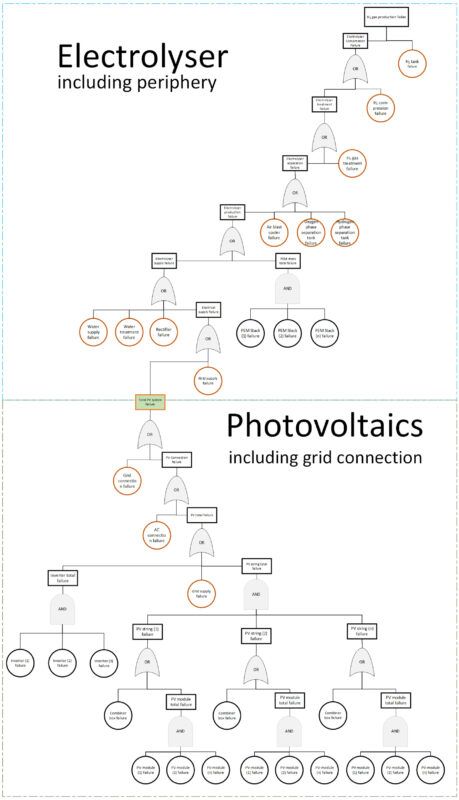

Researchers from the Austrian Institute of Technology have conducted a risk analysis of coupled PV-electrolyser systems and have found that electrolyzers have a higher probability of total system failure compared to the PV plant.

“This paper presents a novel and integrated risk-cost framework for designing and operating coupled PV-electrolyzer systems,” said corresponding author Stefan Niederhofer to pv magazine. “It advances the state of the art by combining fault tree reliability modeling, component-level failure data, and economic evaluation, culminating in a risk-informed techno-economic metric. It is especially relevant for planning next-generation hydrogen infrastructure under real-world constraints.”

The analysis was conducted using fault tree analysis (FTA), based on a combination of scientific literature sources. With that, the team was able to calculate failure probability as well as the levelized cost of hydrogen (LCOH) and its risk-weighted variant (LCOHr).

The academics considered four application scenarios. In scenario 1.1, the directly marketed electricity is billed to the customer via a power purchase agreement (PPA), with the electrical energy being transmitted from the generation site to the electrolysis site via the low, medium, and high-voltage grid. In scenario 1.2, the PV system is on-site, with electrical energy used via the same low- or medium-voltage connection. In both cases, the systems are considered state-of-the-art.

In scenarios 2.0 and 3.0, the system is considered state-of-the-art, featuring either DC-DC direct coupling or DC-DC-rigid direct coupling, respectively. Scenario 2.0 considers directly coupled PV-electrolysis systems with DC-DC direct coupling between the PV system and the electrolyzer via a DC-DC converter. In scenario 3.0, no DC-DC converter was used, and also the peripheral devices are operated to a minimum.

Image: Austrian Institute of Technology GmbH, Renewable Energy, CC BY 4.0

Scenarios 1.1, 1.2, and 2.0 were considered in three use cases: Case 1 included a 5.6 MW PV system, eight inverters, a 1 MW electrolyzer with 4 PEM stacks; case 2 included a 1.2 MW PV system, three inverters, and 1 MW electrolyzer with 4 PEM stacks; case 3 considered a 0.6 MW PV system, one inverter, and 1 MW electrolyzer with 4 PEM stacks. Scenario 3.0 utilizes two other use cases: the first involves 3.2 kW of PV with a 3 kW electrolyzer and one stack, and in the second, the PV system is 9.5 kW, with three electrolyzer stacks of 3 kW each.

“Inverters (PV) and the air blast cooler (electrolyzer system) are most failure-prone. There is significant leverage to reduce system failure through redundant design of both components,” Niederhofer said about the results. “There is a generally higher risk of failure in the electrolyzer system compared to the PV system. Electrolyzer systems have less leverage to reduce the probability of failure because these are technically complex, holistically designed systems.”

Specifically, scenario 1.1 had reliability of 79.97%, 79.89%, and 69.97% for use cases 1,2, and 3, respectively. Scenario 1.2 had reliability of 80.06%, 79.96%, and 70.01% for use cases 1, 2, and 3, respectively. Scenario 2.0 had reliability of 87.21%, 87.2%, and 85.2% for use cases 1, 2, and 3, respectively. Scenario 3.0 had a reliability of 93.99% and 99.97% for use cases 1 and 2, respectively.

“Redundant design of PV inverter can lead to a significant decrease in risk. It leads to a reduction of 60% of the risk-weighted LCOH, LCOHr,” concluded Niederhofer. “It was also shown that the state of science scenarios (DC coupled) also have the potential to produce hydrogen cheaply and reliably. This therefore represents an option for meeting the increasing demand for hydrogen in the future.”

The research work was presented in “Risk analysis of coupled PV-electrolyser systems,” published in Renewable Energy. Scientists from Austria’s Austrian Institute of Technology and Vienna University of Technology participated in the research.

What's Your Reaction?