New approach to measure rear plane-of-array irradiance in bifacial PV plants

Researchers in Denmark claim to have identified the best locations for rear plane-of-array irradiance sensors on the back of single-axis trackers in bifacial PV projects. Their work suggests how to reduce sensor quantities while maintaining accurate performance monitoring.

Researchers in Denmark claim to have identified the best locations for rear plane-of-array irradiance sensors on the back of single-axis trackers in bifacial PV projects. Their work suggests how to reduce sensor quantities while maintaining accurate performance monitoring.

Researchers from Danish PV project developer European Energy and the Technical University of Denmark have outlined a new methodology for rear irradiance monitoring bifacial photovoltaic systems relying on trackers.

“The goal of the research was simply to figure out where to put pyranometers on the back of utility-scale bifacial tracking systems, and how many pyranometers are needed to accurately measure rear irradiance,” the research's corresponding author, Nicholas Riedel-Lyngskær, told pv magazine. “This is important to know for accurate performance monitoring and PV plant acceptance testing.”

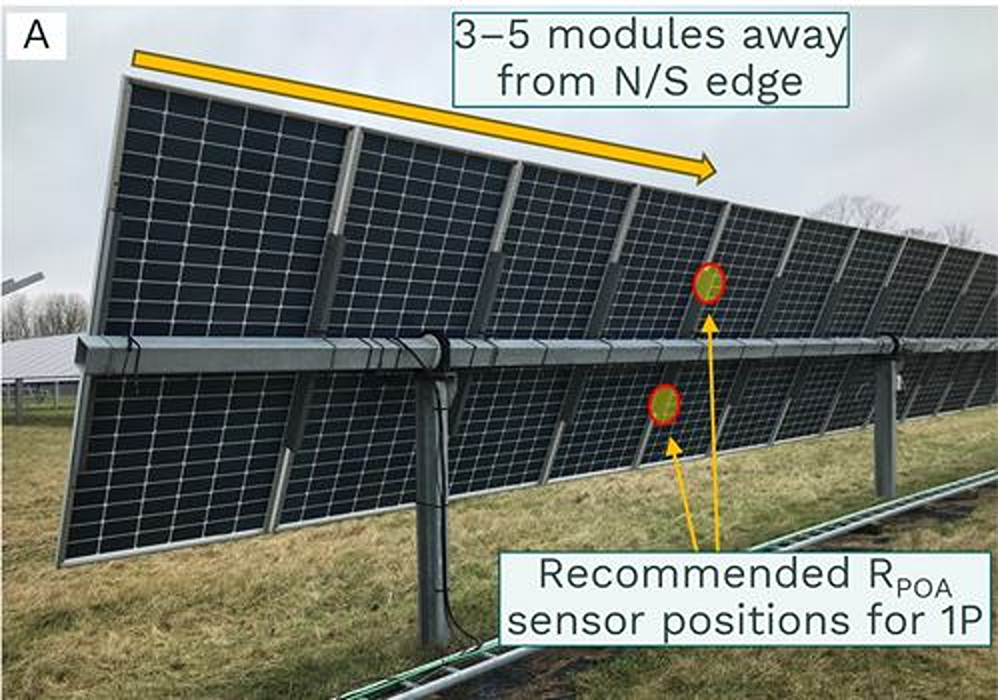

The scientists claim to have identified the best locations for rear plane-of-array irradiance sensors on the back of single-axis trackers in bifacial PV projects. “With raytracing and some field validation, we were able to make very specific recommendations for rear pyranometer placement and quantities on 1P, 2P and 2P-gap trackers, which means the most common ones,” Riedel-Lyngskær added.

In the paper “Rear irradiance monitoring on tracked bifacial photovoltaic systems,” which was recently published in Solar Energy, the research team explained that the PV industry has not yet identified the best practices for performing rear plane-of-array (RPOA) irradiance measurements. As a solution, it proposed simulating spatio-temporal light distributions on the back of large-scale single-axis trackers (SATs) projects in nine climates using the open-source Python library bifacial radiance.

The academics also noted that the IEC 61724–1 provisions for RPOA irradiance measurements do not provide many details on sensor positioning, nor provide clarity on sensor quantities.

They used a high-performance computer (HPC) to perform hourly raytracing simulations of existing SAT bifacial PV projects at nine locations around the world: Accra, Ghana; Badajoz, Spain; Bandar Seri, Brunei; Charleville; Australia; Heilongjiang, China; Kastrup, Denmark; Minya, Egypt; Spring Lake, Canada; and Xinjiang, China.

For each SAT type, they modeled a five-row tracker system where each tracker has 22 modules in series. “This approach is informed by several seminal bifacial simulation works that demonstrated the center module within a five-row system closely approximates the irradiance received by a PV array of semi-infinite length,” the paper notes.

RPOA irradiance was simulated at 23 discrete points on the back of the center module, with the analysis including 20 evenly spaced points from east to west in the backside plane-of-array (POA), one directly on the torque tube (TT) facing the ground underneath the center module, and two at the north and south end of the TT.

The simulations showed that there is no single position on the backside of SATs that accurately matches the spatially averaged RPOA irradiance. The best single RPOA location was found to have a mean error of 7%, which the scientists were able to reduce to 2% by averaging measurements at just two discrete locations on the east/west sides of SATs.

“The addition of a third RPOA sensor in the average did not decrease the error, which suggests that future revisions of IEC 61724–1 should specify RPOA sensor quantities to scale by a factor of two, instead of the current factor of three;” the research team stressed, noting that the results only apply to SATs with a TT aligned in the north-south direction. “Optimal sensor placement for equator-facing fixed-tilt, vertically mounted east-west, or overhead agrivoltaic structures must be evaluated for the specific project, and could be the subject of future work.”

According to Riedel-Lyngskær, the IEC 61724–1 standard currently requires 33% more rear sensors than are necessary to accurately monitor a PV plant. “Our recommendations result in reduced costs without compromising the accuracy of rear irradiance measurements,” he concluded. “The IEC 61724-1 project team has now invited me to work on the next edition of the standard, but we hope that the paper can support and harmonize guidelines in other solar tracker-related standards.”

What's Your Reaction?