Suntex integrates organic PV into sturdy textiles for outdoor use

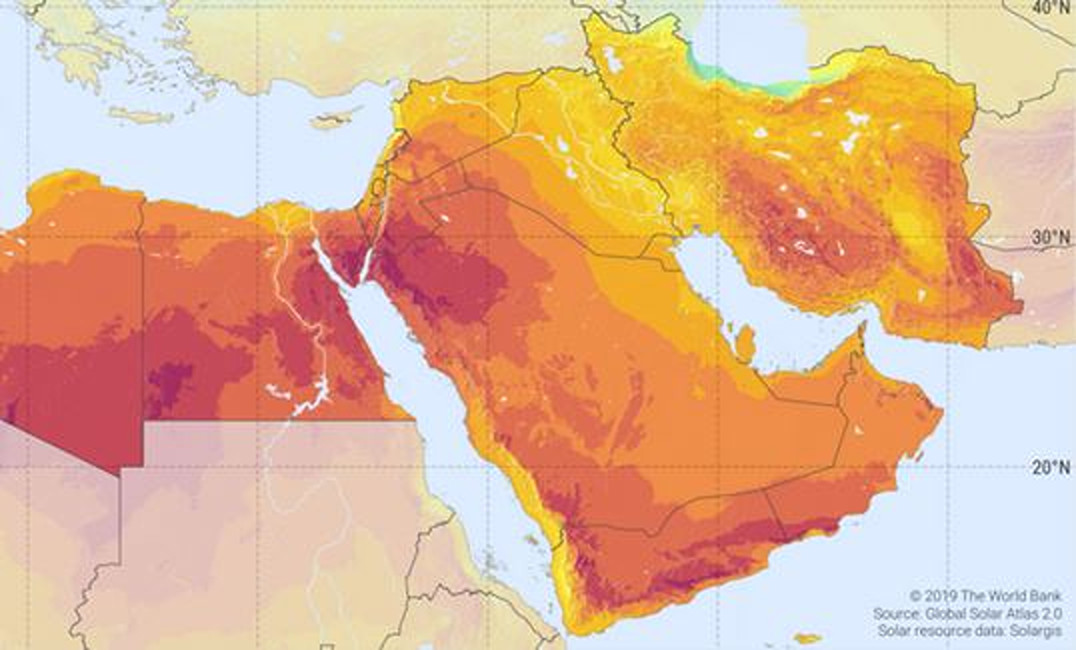

A European team from industry and academia is integrating organic solar cells into woven polyester textiles for outdoor use, such as in tents or canopies. The Suntex project also focuses on improving the durability and efficiency of organic photovoltaics.

A European team from industry and academia is integrating organic solar cells into woven polyester textiles for outdoor use, such as in tents or canopies. The Suntex project also focuses on improving the durability and efficiency of organic photovoltaics.

European researchers from industry and academia are integrating organic thin-film photovoltaic cells (OPV) into woven textiles for use in lightweight outdoor structures, such as tents or canopies.

The Suntex project includes work on improving OPV durability and efficiencies. It is a three-year €2.13 million ($2.47 million) Eurostars-funded initiative.

“We focus on outdoor applications like textile facades, festival tents, and shade structures. So our textile needs to withstand all kinds of influence from the environment, like UV, wind, and water. Of course, we also foresee indoor applications like curtains/sun shading,” project leader Pauline van Dongen told pv magazine.

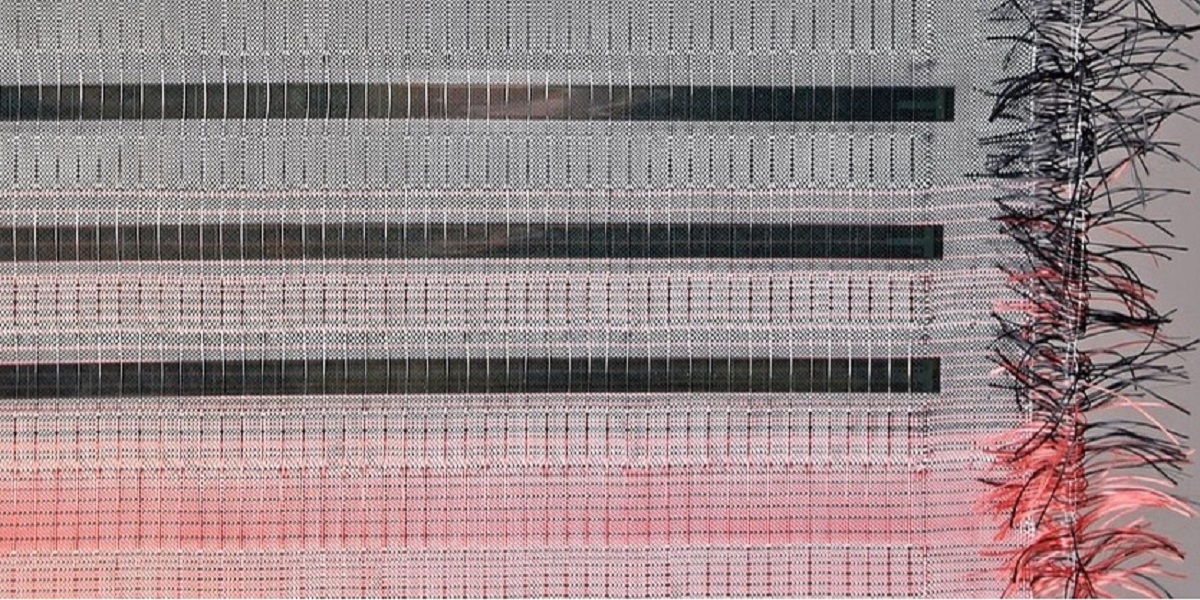

The novel textile, which shares the same name as the project, is made of strips of encapsulated OPV woven into panels made with recycled high-strength polyester threads and fabricated in a polyester weaving process.

Differentiating Suntex from earlier textile-integrated PV concepts that laminate thin-film solar cells onto existing textiles, van Dongen said, “We’re working with a modular system where we can separate the textile, organic photovoltaic cells (OPV), and circuitry. It allows us to repair and upgrade the material with more efficient OPV panels when they become available,” he stated.

OPV technology was reportedly chosen as it contains no harmful chemicals, can be printed in any shape, and is flexible, while the chosen textile uses recycled high-strength polyester threads. A single thread typically consists of hundreds of fibres, and one can carry up to 9 kg, according to the team. Five cm of the textile can reportedly withstand 300 kg.

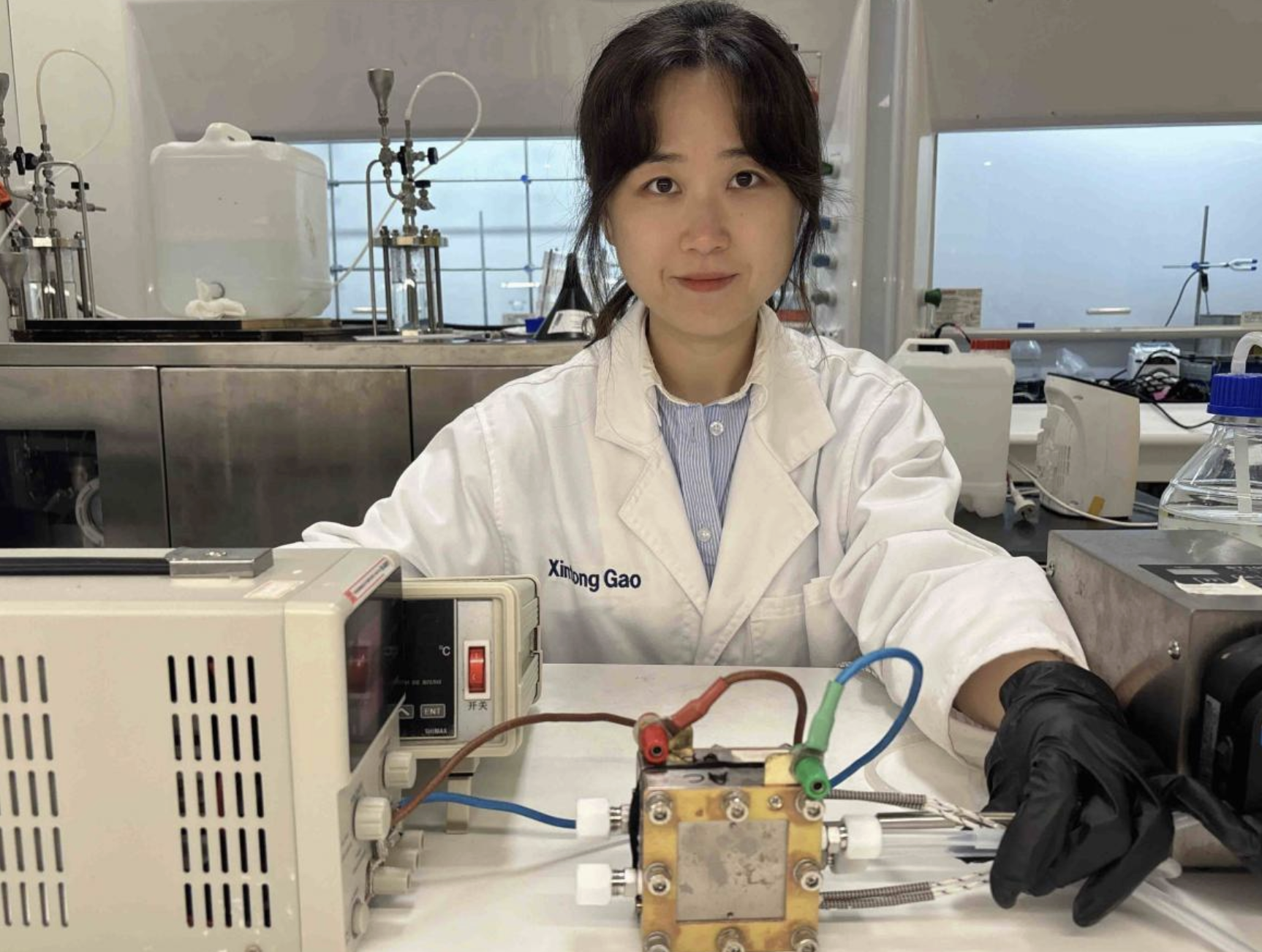

The group has high-performance OPV targets that are not disclosed. It plans to work on encapsulation, new organic materials, and novel configurations. “For encapsulation, we look into a variety of flexible barrier materials, and we do use roll to roll (R2R) techniques for the full OPV fabrication process,” Morten Madsen, of project partner University of Southern Denmark (SDU) told pv magazine.

Two of the project partners have been working on this type of textile since 2021, namely Pauline van Dongen Innovations BV and Tentech BV, an architecture and engineering company specializing in lightweight structures, both based in the Netherlands. They are joined in this project, by SDU, Rheinisch-Westfälische Technische Hochschule Aachen (RWTH), Kettler Berufskleidung & Technische Textilien GmbH, and Grafisk Maskinfabrik A/S.

What's Your Reaction?