PEM Electrolysis Makes Strides in Cutting Hydrogen Production Costs in China and Europe

Proton Exchange Membrane (PEM) electrolysis is no longer just a lab experiment—it’s showing up ready for the big leagues. Backed…

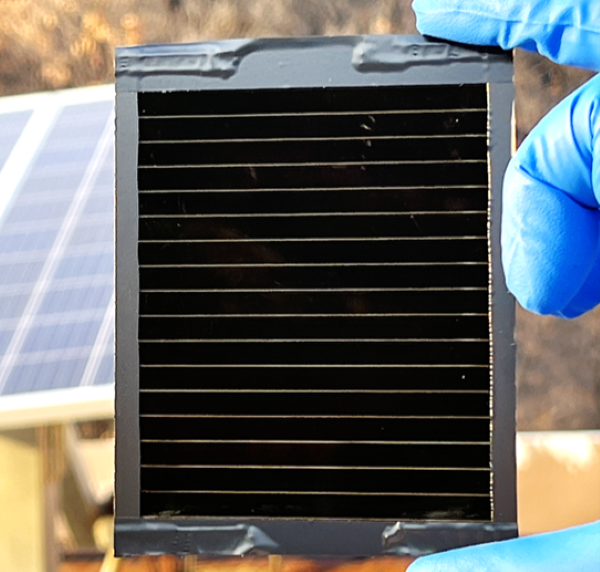

Proton Exchange Membrane (PEM) electrolysis is no longer just a lab experiment—it’s showing up ready for the big leagues. Backed by hands-on results from a 190 Nm³/h platform in China and fresh optimizations by researchers in Germany, PEM electrolysis is offering more than just solid tech. It’s also starting to look like a real contender in the race to bring down the cost of large-scale green hydrogen production.

China and Germany Team Up — Performance Meets Practicality

Finalized in mid-2025, a new study digs into how PEM electrolyzers stack up for grid-level hydrogen production. The focus? How they respond under pressure—literally. Think startup and shutdown dynamics, clever grid integration, and smart pathways to get PEM units out of the lab and into the field. Three big names are involved:

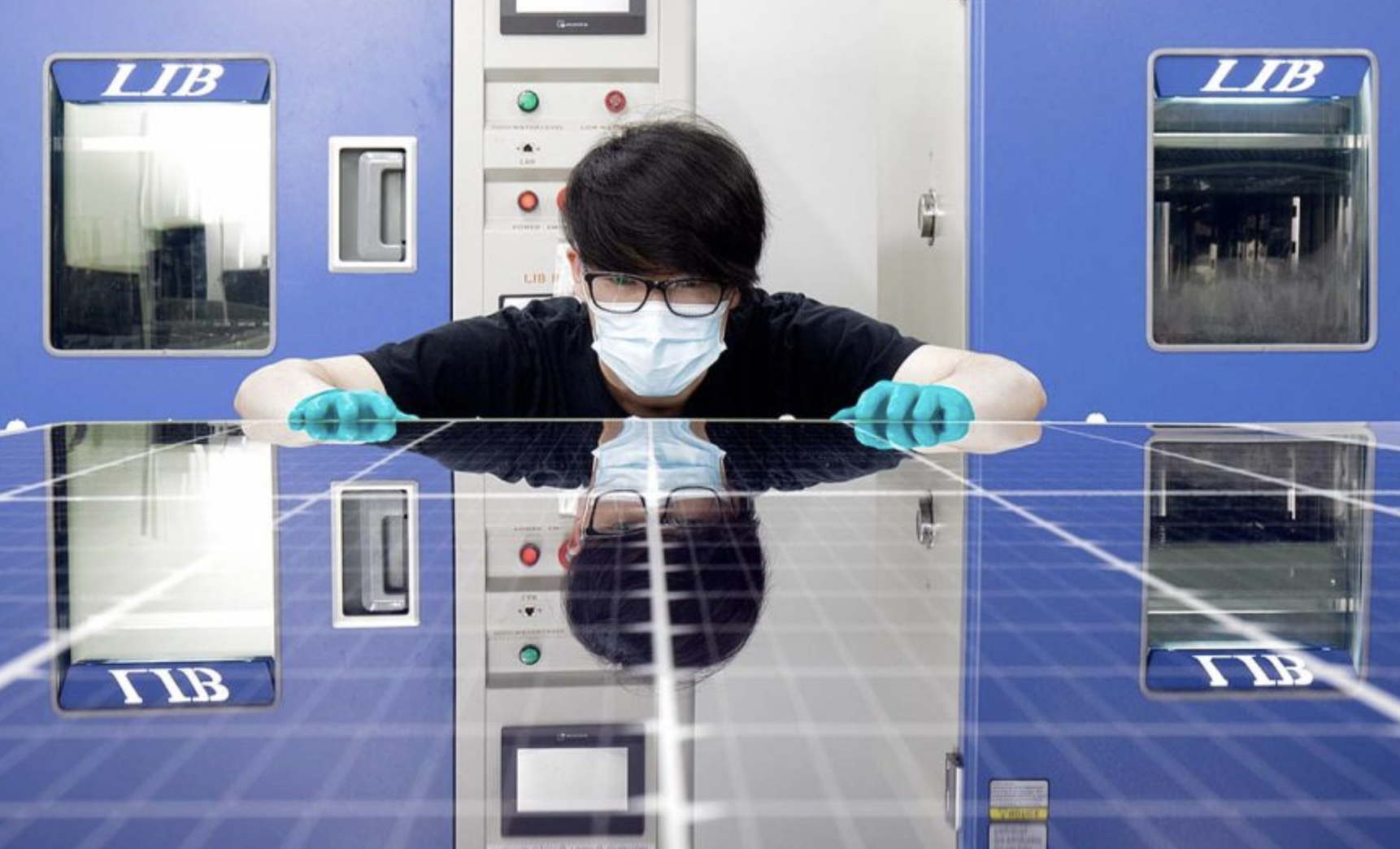

- Zhang et al. in China, who created a high-temp membrane that handles stop-start cycling like a champ.

- Bornemann et al. in Germany, who managed to bring down power usage by around 4–7% through fine-tuning system operations.

- Bosch, gearing up to release industrial-sized PEM stack systems in 2025 under the Hybrion line.

Much of this progress is being driven by momentum in China, where hydrogen infrastructure development is moving fast. With low industrial overhead—about $200 per capita—and clear national guidelines, China is acting as a proving ground for scalable PEM rollouts that make sense from a cost and utility perspective.

Start-Stop Stress Test: Speed and Control in Real-World Conditions

We’ve always known that PEM electrolysis is fast on the draw, and now we have the receipts. Cold starts average around 6340 seconds, while thermal starts take about 1100 seconds. Shutdowns come in at 855 seconds. Sure, that’s not instant-on like a battery, but with hydrogen purity above 99.9%, PEM is standing tall where it counts—especially in industrial scenarios.

These traits are tailor-made for China’s increasingly renewables-heavy grid. With solar and wind creating power peaks and valleys, electrolyzers that can ride those waves and stabilize energy supply are critical. Added features like smart preheating and built-in gas-liquid separation tech improve reliability and safety—something every operator can appreciate.

Momentum Grows: Lower Costs and Smarter Integration

Let’s talk dollars and sense. With new optimizations and mass production on the way, PEM-based hydrogen production costs are projected to drop by over 60%. This isn’t just pie-in-the-sky forecasting—these numbers are tied to real-world engineering tweaks and the cost benefits of scaling up. According to Zhang’s team, the magic happens when you mix better materials with higher production volumes. And they’re not wrong.

Bornemann’s work shows that dialing in performance—how much the system runs, how fast it ramps—has a real impact on operational cost, not just lab results. That’s a big deal. It opens up a future where PEM electrolyzers can sit directly next to wind or solar farms, acting both as a power buffer and as a generator of clean hydrogen.

All-In on Scale: Bosch Prepares for 2025 Launch

Bosch isn’t dipping a toe in—they’re diving headfirst. Set to roll out their full-blown Hybrion PEM systems in 2025, they’re moving from proofs of concept to full industrial-scale units. That shift from prototype to production could be what finally drives real, bankable cost reduction through standardization and sheer manufacturing muscle.

For Bosch, this isn’t just about selling units. It’s about building the nuts and bolts of a new energy economy—one where hydrogen becomes a core piece of the zero-emissions puzzle.

Why This Tech Really Matters

Zoom out a little, and PEM electrolysis starts to look like a Swiss Army knife for the energy transition. It can help clean up heavy industry, support shaky power grids, fuel hydrogen mobility projects, and feed clean hydrogen into everything from fertilizers to fuels. But it’s not all smooth sailing.

Yes, PEM tech relies on rare platinum group metals, so we’ll need better recycling and better sourcing to scale responsibly. And don’t forget the water—electrolysis is thirsty work, which becomes a real concern in dry regions or where desalination is required first.

Safety’s non-negotiable too. Hydrogen burns hot and fast, so built-in monitoring systems, clever logic controls, and advanced safety protocols are all must-haves—not optional add-ons.

Where It’s Going: Reality > Hype

This isn’t the future—it’s already happening. Sure, PEM electrolysis systems still come with high up-front costs, but with smart engineering (like Bornemann’s) and material breakthroughs (thanks to Zhang’s team), we’re seeing those barriers come down fast.

When paired with large renewable assets, PEM tech isn’t just keeping up—it’s standing out. China brings the policy clarity and scale, Germany brings the tech precision. Together, they’re charting a realistic course toward bankable, scalable green hydrogen systems.

Once Bosch hits the industrial stage in 2025, expect pushback from traditional fossil investors—but also a big uptick in spotlight and capital flowing toward electrolyzer startups and supply chains. If you’re paying attention to the next big leap in clean energy, keep your eyes on PEM systems. This isn’t just an energy source—it’s the backbone of a modular, distributed, and renewable-first world.

What's Your Reaction?